Utility Diagnostics Tool

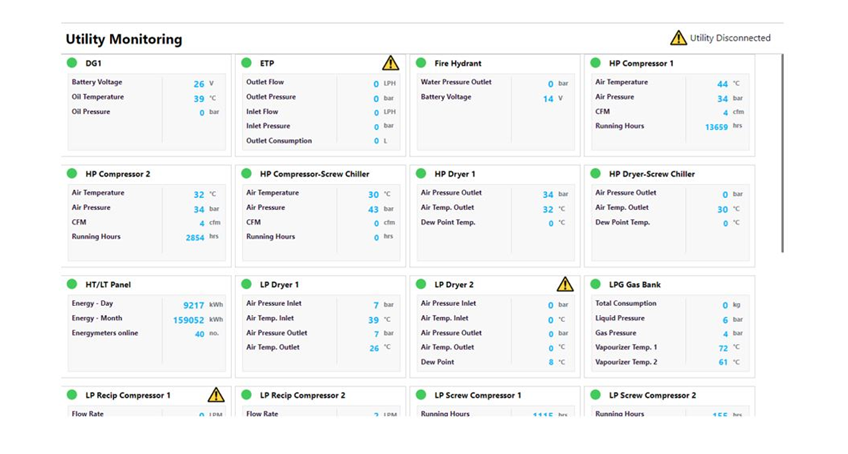

Unified Dashboard.

All utilities in the factory like compressor, dryers, ETP, STP plants etc. can be connected and can be bought to a single dashboard for analysis.

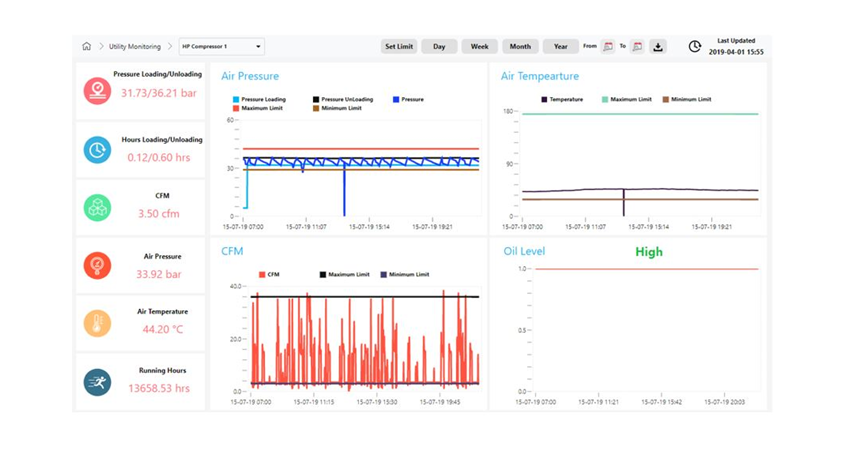

Analyze the daily usage.

Daily usage of these utilities inn terms of their critical parameters can be monitored continuously in the application.

Connect all utilities.

Different utilities require different parameters to be monitored. Retrofit the required sensors (iotedge.store) and integrate the same to the app to get the continuous data.

Alerts and Notification.

Users can self-configure the alert threshold limits for all utilities. Automatic alert and notification will be enabled based on the threshold limits.