Gas Flow Monitoring Tool

Immediate Maintenance by monitoring the gas flow.

Industrial operations often consume a lot of LPG at a very fast rate. Sometimes it becomes difficult to manually keep a track of the fuel levels. Many applications require accurate flow rate measurement for air or other gases. Installation requirements, calibration and maintenance are among the factors that must be considered when selecting a flow-measurement technology.

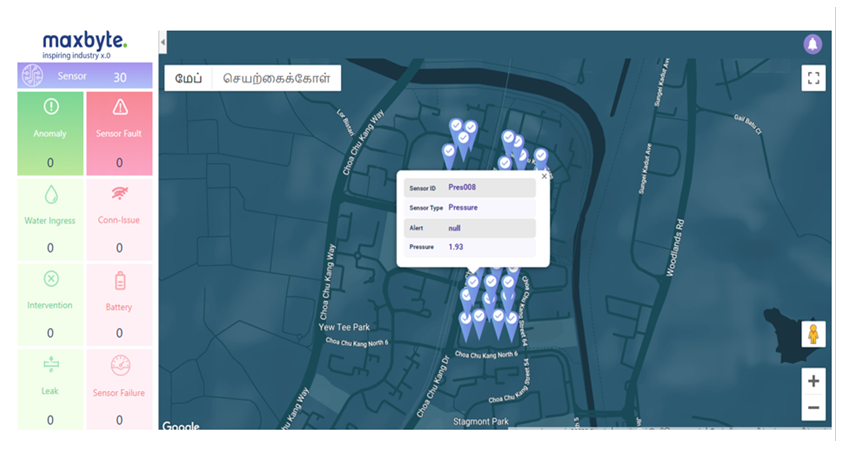

Condition Monitoring.

Monitoring of the specific parameters with respect to the gas flow conditions to be done remotely. The configuration of the parameters can also be done with respect to the need.

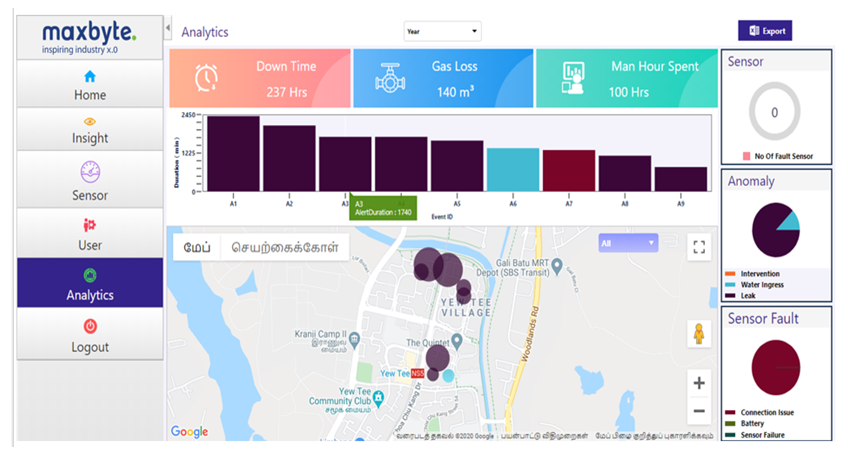

Ticket Generation on Anomaly.

On exceeding the conditions that is been configured, a ticket will be raised and an alert is to be generated to the maintenance person.

Ticket Progress Monitoring.

Progress in the ticket is to be monitored by the maintenance team. Ticket must be closed once the Maintenance work is completed by Engineer.