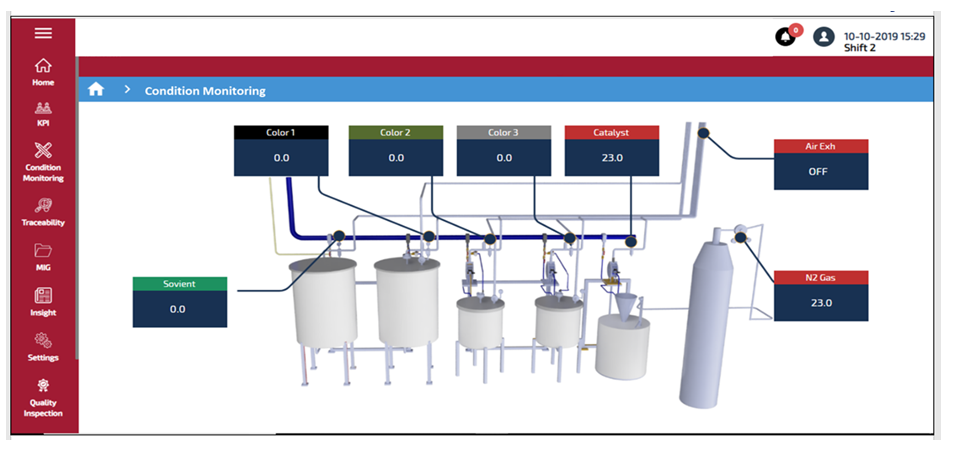

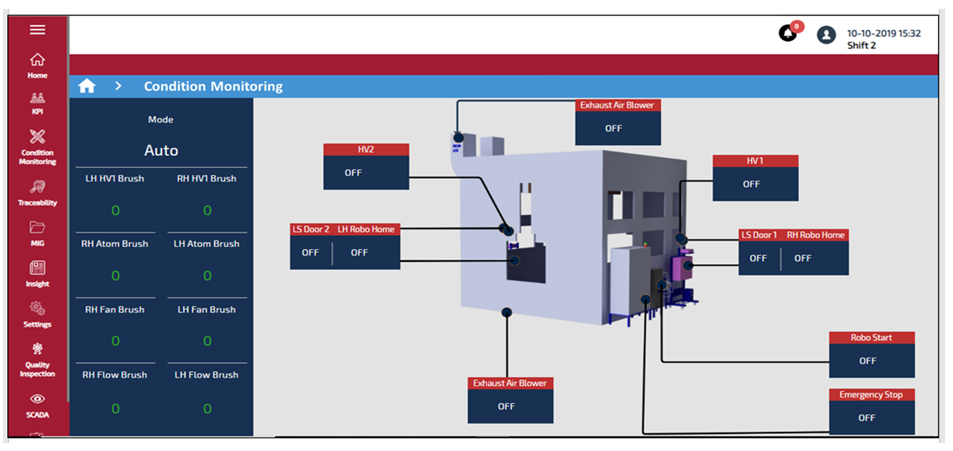

Condition Monitoring System

Continuous monitoring of factory.

Condition Monitoring is the process of monitoring a parameter of condition in machinery and it allows maintenance team to monitor the shop-floor equipment & asset health conditions and status remotely. Real-time conditional anomaly alerts to notify maintenance team before it creates production downtime.

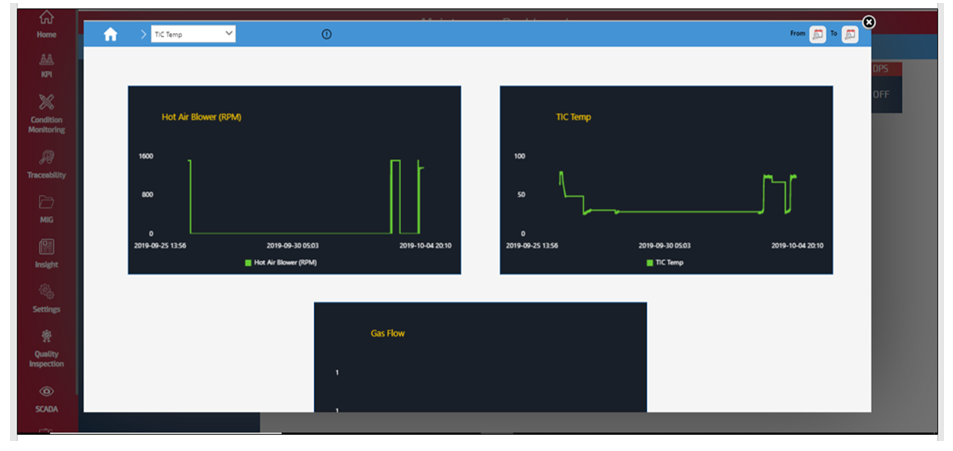

Capture Key Parameters.

Capture the key condition monitoring parameters like Vibration, Pressure, Temperature etc. from the machines and utilities to monitor the real time data with help of sensors and hardware devices.

Handle Asset Lifecycle.

Condition Monitoring app allows to calculate the useful life for any asset by continuously monitoring the life critical parameters. These parameters can be directly monitored from machine or can be monitored by retrofitting the required sensors.

Set threshold limit for Remote Monitoring

This app allows users to easily configure the required parameter and the threshold limits for the required parameters. These parameters can be monitored from any remote place to get the real time data.

Alerts & Notification.

Get real time alerts and notification on the condition monitoring parameters through SMS and email.