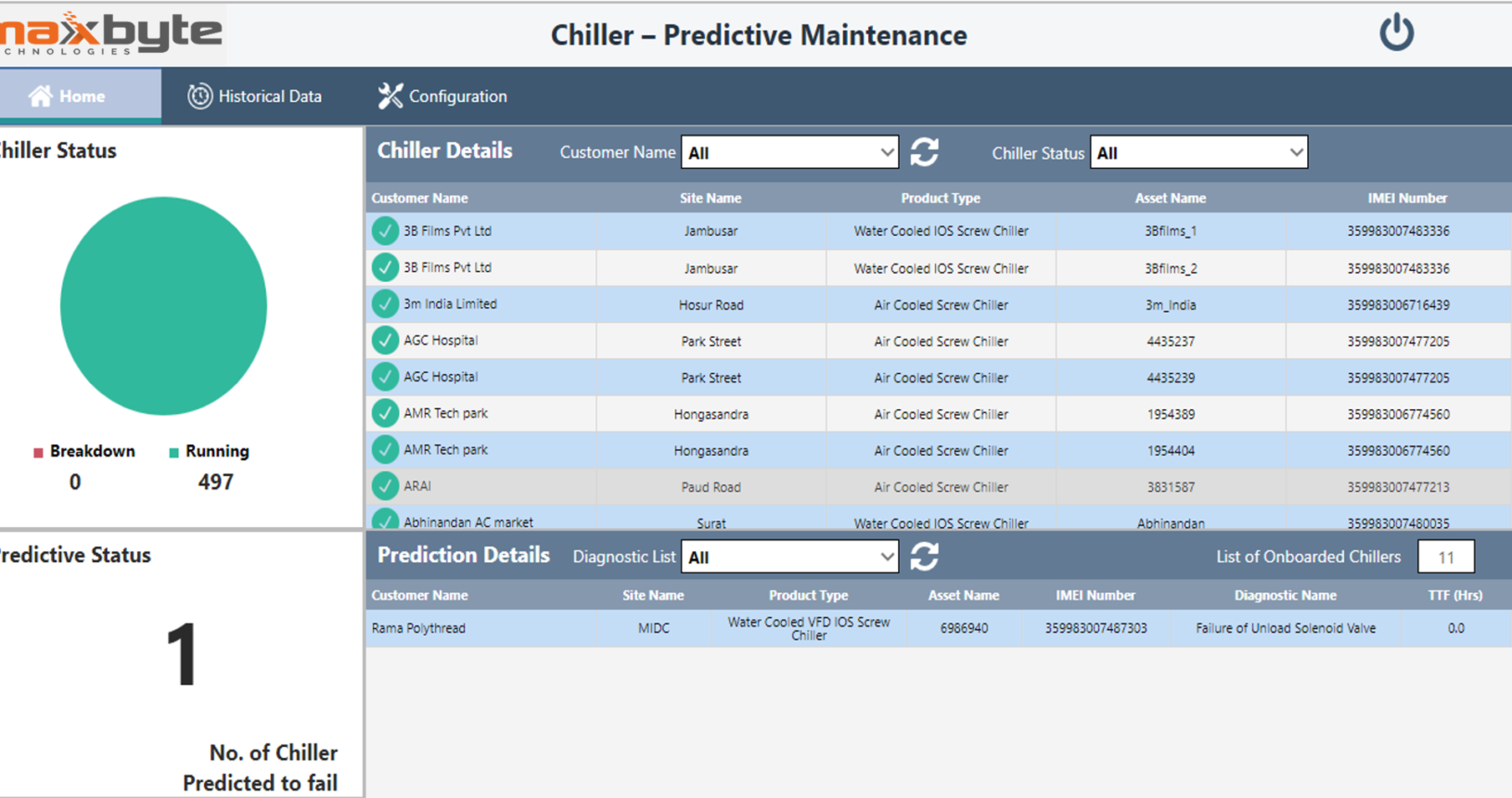

Chiller Analyzer

Predict your chiller failures effectively.

What if you could predict when your chiller will go down? And stop it from happening? It would mean saving time and money and keeping occupants happy and comfortable. Today, with the help of a cloud-based analytics platform and embedded intelligence, it’s possible to monitor chiller performance from anywhere and fix problems before they start.

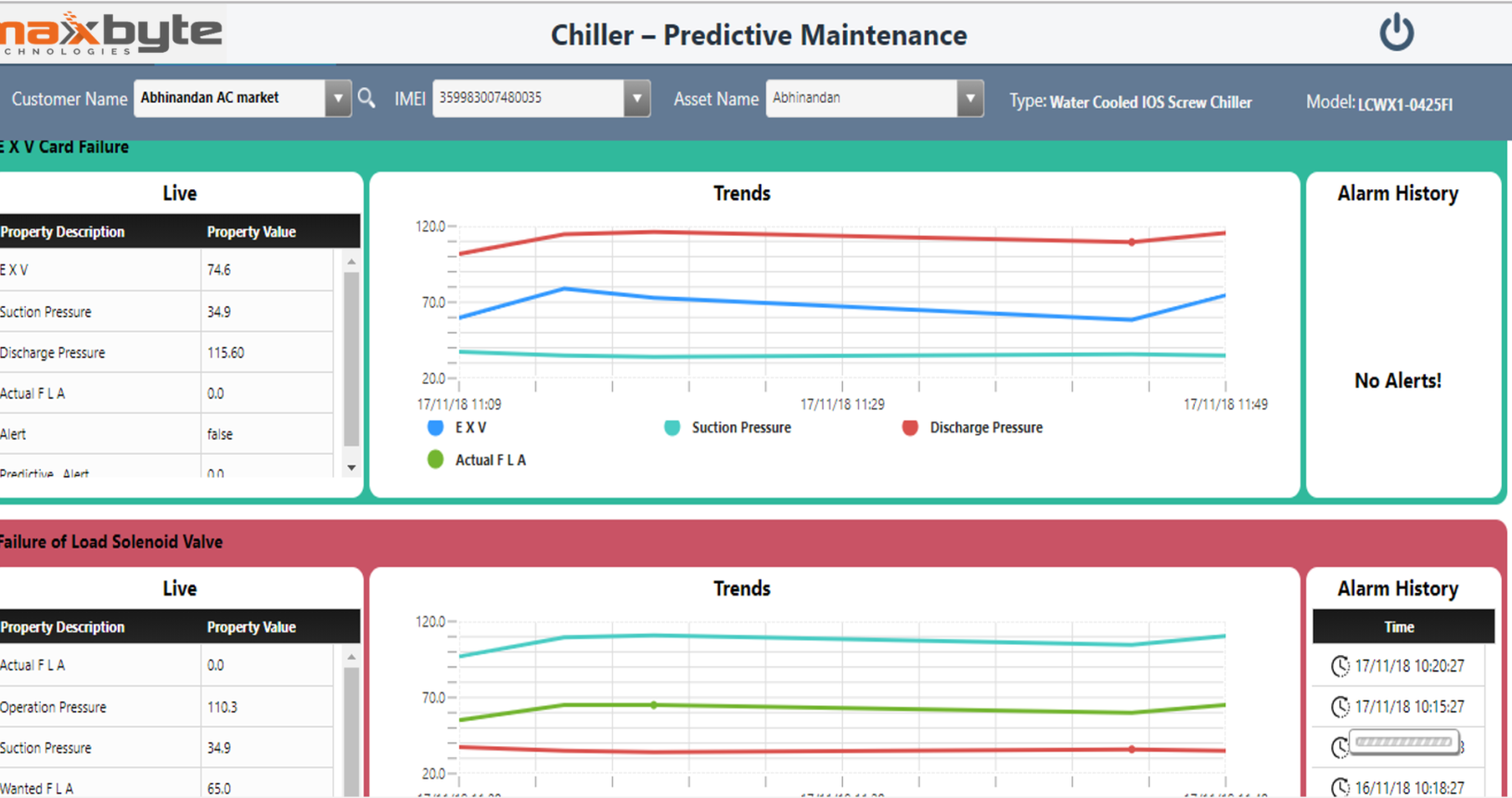

Prediction tool.

Predict failures in Chiller for proactive maintenance. Hourly consumption forecast for the next day, 1-4 hourly forecast for the next week.

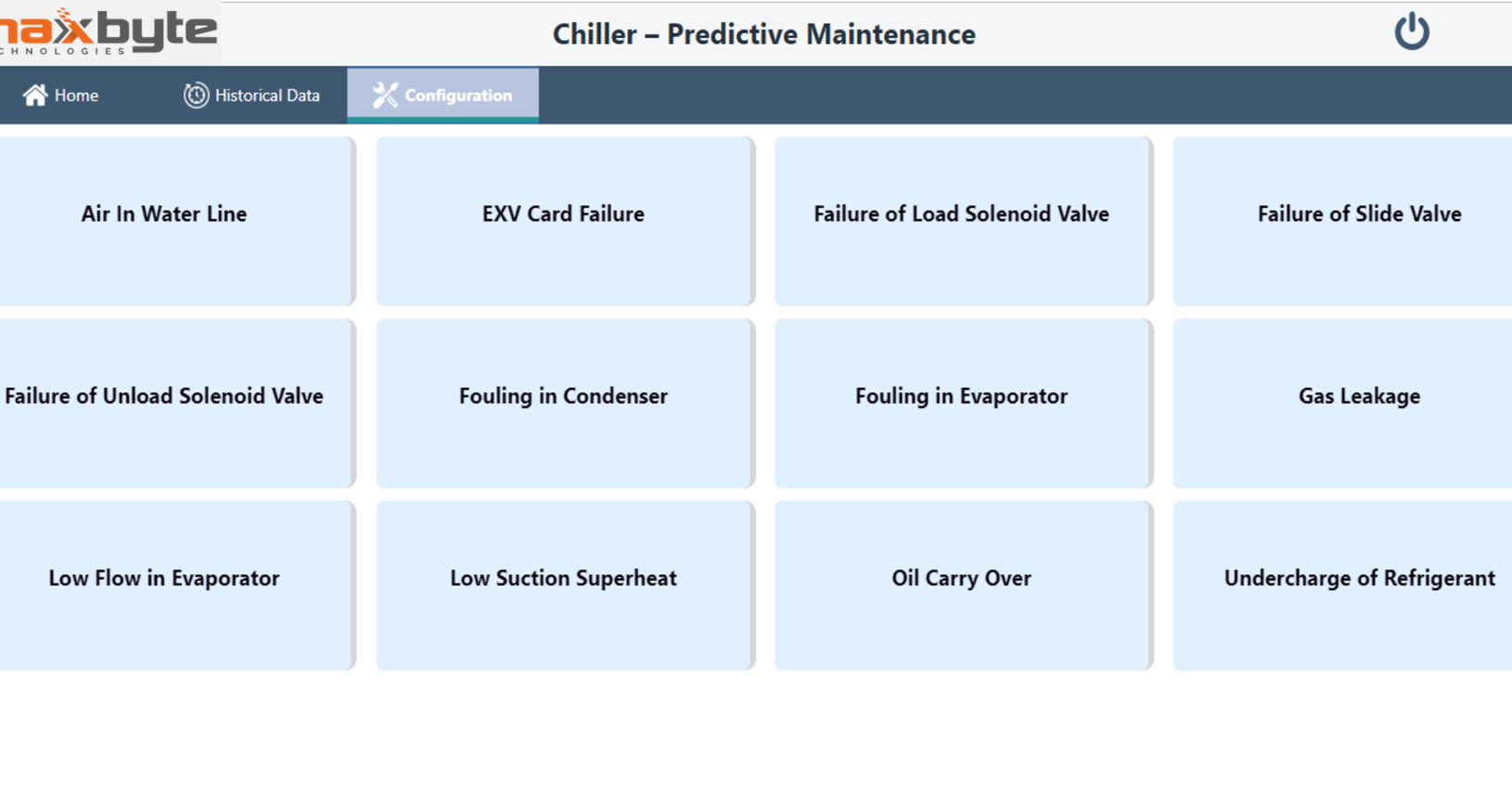

Smart tagging

An online tool allowing the user to tag special events and create his own alerts for similar events in the future.

Smart alerts.

Based on self-learning, the system automatically identifies over/under consumptions as well as failure of equipment.