From Language Models to Autonomous Agents: The Evolution of Generative AI

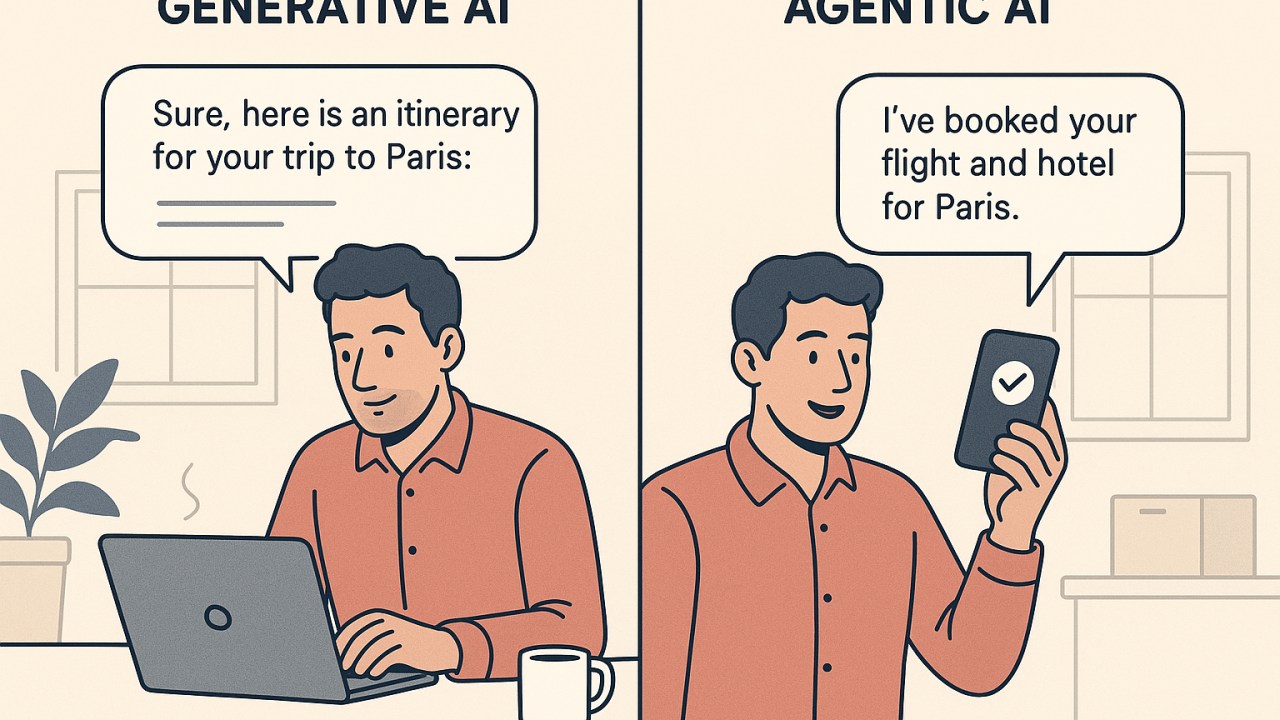

The journey of Generative AI began with large language models (LLMs) like GPT, which could understand and generate human-like text. These models revolutionized how we interact with machines—enabling everything from chatbots to content creation.

Now, we’re entering the era of autonomous agents – systems that not only understand language but can plan, act and adapt to achieve goals independently. These agents are built on top of LLMs but go further: they monitor environments, make decisions and execute tasks across digital systems.

In manufacturing, this evolution means moving from static automation to dynamic, intelligent systems that optimize operations in real time.

Generative AI Agents Are Like Google Maps for Your Factory

Imagine your factory is a city. You have multiple routes (production lines), traffic (machine breakdowns) and destinations (output goals). A generative AI agent acts like Google Maps:

- It constantly monitors traffic (real-time machine data).

- It suggests the fastest route (optimized workflows).

- It reroutes you instantly if there’s a roadblock (supply chain disruption).

- It learns from every trip to improve future decisions.

Just like you wouldn’t drive without navigation in a new city, AI Agents are vital in seamlessly operating the modern factories.

How Generative AI Agents Enhance Manufacturing Processes

Generative AI agents are not just futuristic concepts – they’re practical tools reshaping how factories operate today. By embedding intelligence into everyday workflows, these agents help manufacturers move from reactive decision-making to proactive, data-driven operations. Below are five key areas of the many where generative AI agents are making a measurable impact.

1. Predictive Maintenance

Current Process: Maintenance is often scheduled based on fixed intervals or reactive responses to breakdowns.

With Generative AI Agents: Agents analyse sensor data in real time, detect anomalies and predict failures before they happen.

Benefit: Up to 50% reduction in unplanned downtime (McKinsey).

2. Generative Design

Current Process: Engineers manually iterate designs using CAD tools, often constrained by time and experience.

With Generative AI Agents: Agents generate multiple design options based on performance goals, material constraints and cost targets.

Benefit: Faster prototyping and optimized designs with reduced material waste.

3. Process Optimization

Current Process: Operators rely on historical data and manual adjustments to improve throughput or reduce energy use.

With Generative AI Agents: Agents continuously monitor production data and suggest real-time adjustments to parameters.

Benefit: 20–30% improvement in productivity (BCG).

4. Supply Chain Resilience

Current Process: Supply chain planning is static and vulnerable to disruptions.

With Generative AI Agents: Agents simulate disruptions (e.g., supplier delays) and recommend adaptive strategies instantly.

Benefit: Improved agility and reduced risk exposure.

5. Workforce Augmentation

Current Process: Operators rely on manuals or supervisors for troubleshooting and decision-making.

With Generative AI Agents: Agents provide live guidance, dynamic work instructions and contextual decision support.

Benefit: Reduced training time and improved operational consistency.

While these five use cases represent some of the most impactful applications of generative AI agents in manufacturing, they are just the beginning. The true power of these agents lies in their flexibility and scalability—they can be custom-built to address unique operational challenges, integrate with existing systems and evolve with your business needs.

Whether it’s energy optimization, real-time compliance monitoring or adaptive workforce scheduling, the possibilities are vast and tailored innovation is well within reach.

Tangible Business Benefits:

According to McKinsey, generative AI in manufacturing and supply chains could reduce operational expenses by up to $500 billion globally. Early adopters are already seeing:

- 20–30% improvement in productivity

- Up to 50% reduction in downtime

- Faster time-to-market for new products

- Enhanced sustainability reporting and compliance

These agents are also compliant with major standards and frameworks, with many platforms offering pre-configured reports for ESG, ISO and GHG protocols.

Limitations and Long-Term Value

While the potential is massive, generative AI agents are not without challenges:

- Data quality and integration: Poor data can limit effectiveness.

- Change management: Teams need training and trust in AI decisions.

- Initial investment: Requires upfront cost in infrastructure and talent.

However, these are short-term hurdles. As Gartner emphasizes, organizations that invest early in generative AI agents will be better positioned for long-term resilience, innovation and sustainability.

Final Thoughts

Generative AI agents are not just a technological upgrade—they represent a strategic shift in how manufacturing operates. From predictive maintenance to autonomous decision-making, these agents are redefining what’s possible on the factory floor.

“The future of manufacturing is intelligent, adaptive and AI-driven – and it’s already here”