Your Cart Is Empty

✖No products in the cart.

Strategic and Operational Insights of the Production Facilities for CXOs to sustain business performance in the competitive environment

Improving visibility and transparency at each stage of Manufacturing Operations

Easy-to-configure, user-friendly digital apps for technicians and workers to review and execute paperless shopfloor operations

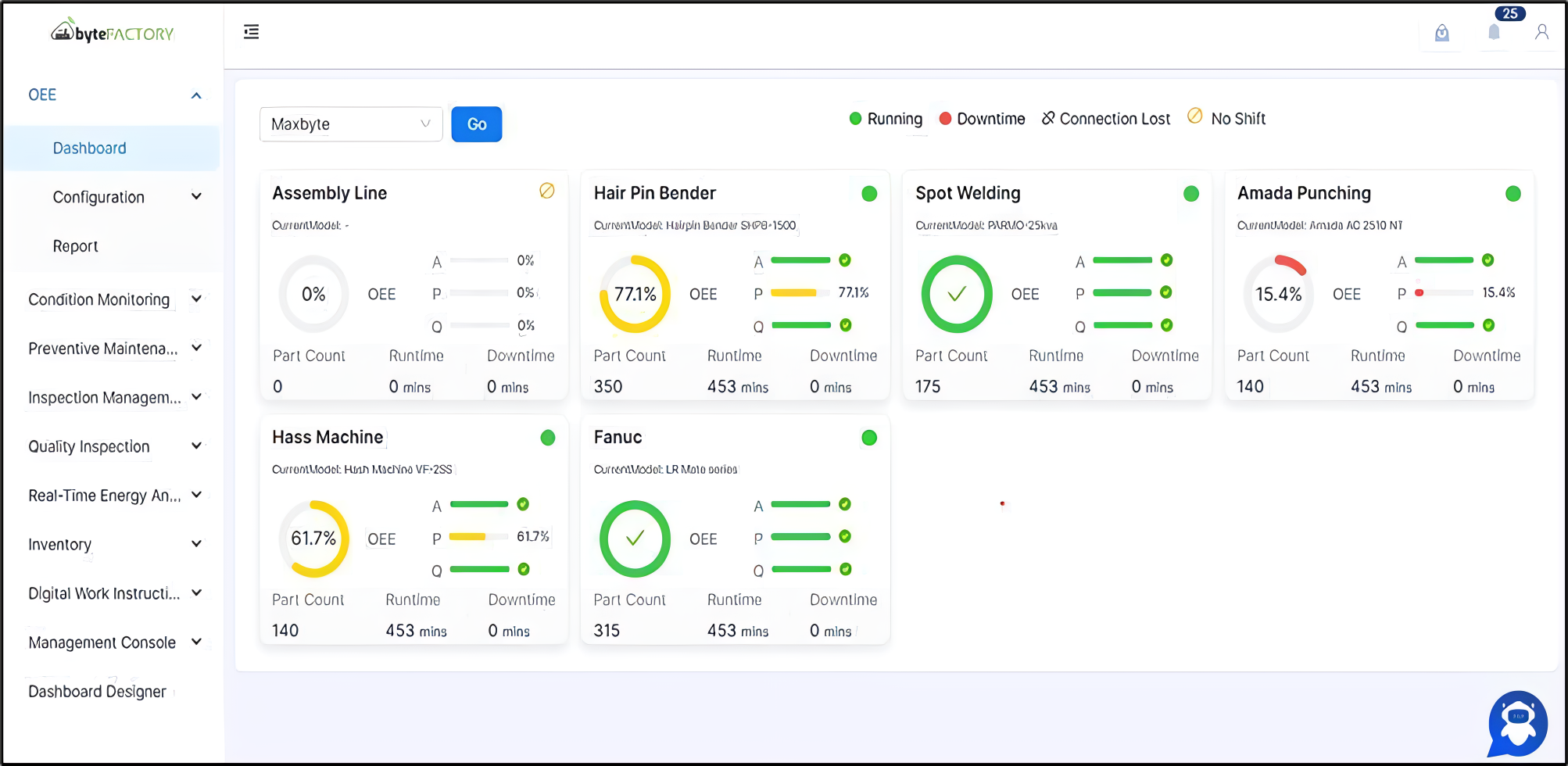

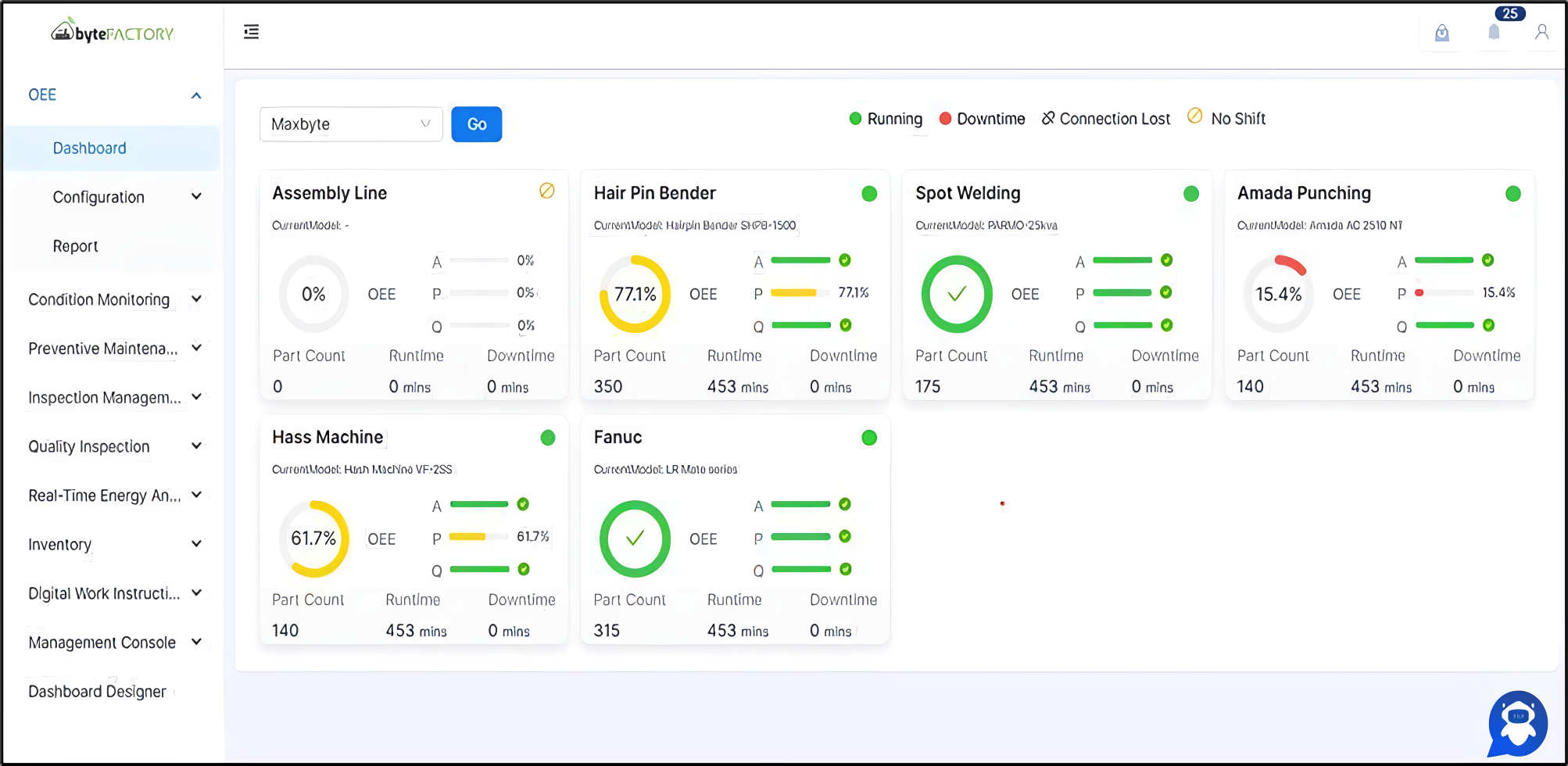

Solution to monitor OEE, Productivity, Utilization and Quality to maximize output while minimizing losses and downtime.

Use of Machine data and sensor data and advanced analytics to monitor the real-time condition of machinery to predict potential faults or failures

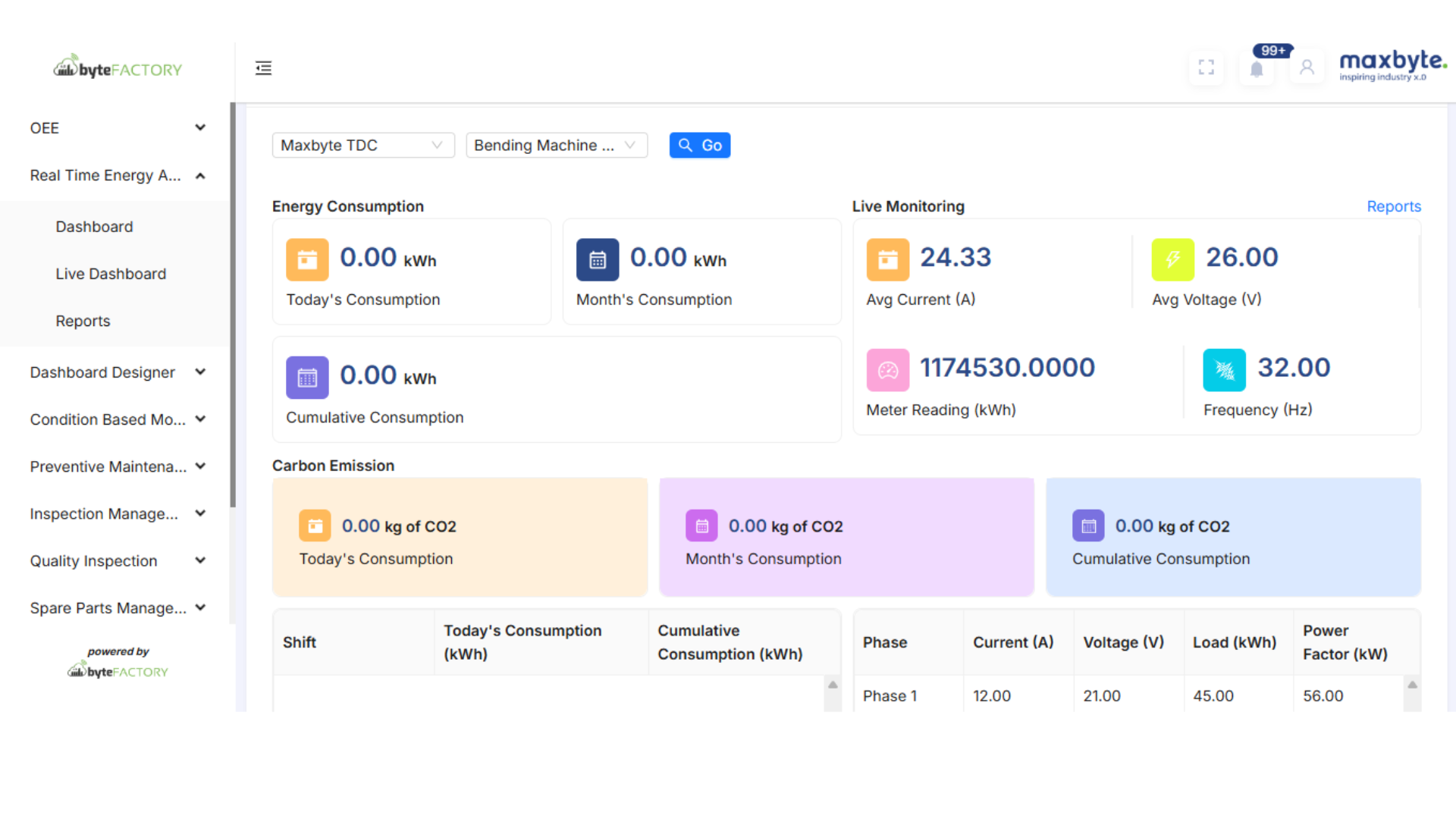

Energy Monitoring is a critical sustainability and cost-optimization strategy that involves tracking and analyzing.

Smart solution to schedule, track and optimize all maintenance activities for improved uptime and asset life.

Spare Parts Management ensures the right parts are available when needed minimizing downtime.

OEE (Overall Equipment Effectiveness) is a powerful performance metric used in manufacturing to evaluate the efficiency of production processes. OEE measures how well a manufacturing concern optimizes its equipment, labor and time to maximize output while minimizing losses and downtime.

Condition Based Monitoring (CBM) is a proactive maintenance strategy that involves the use of sensor data and advanced analytics to monitor the real-time condition of machinery and equipment. By continuously collecting and analyzing data on various parameters like vibration, temperature, pressure and other performance indicators, CBM enables manufacturers to predict potential faults or failures before they occur, allowing for timely and cost-effective maintenance interventions

Energy Monitoring is a critical sustainability and cost-optimization strategy that involves tracking, analyzing and managing energy consumption across manufacturing operations. By using smart meters and real-time analytics, manufacturers can identify energy-intensive processes, detect inefficiencies and reduce operational costs. This data-driven approach supports compliance with energy regulations and promotes environmentally responsible manufacturing practices.

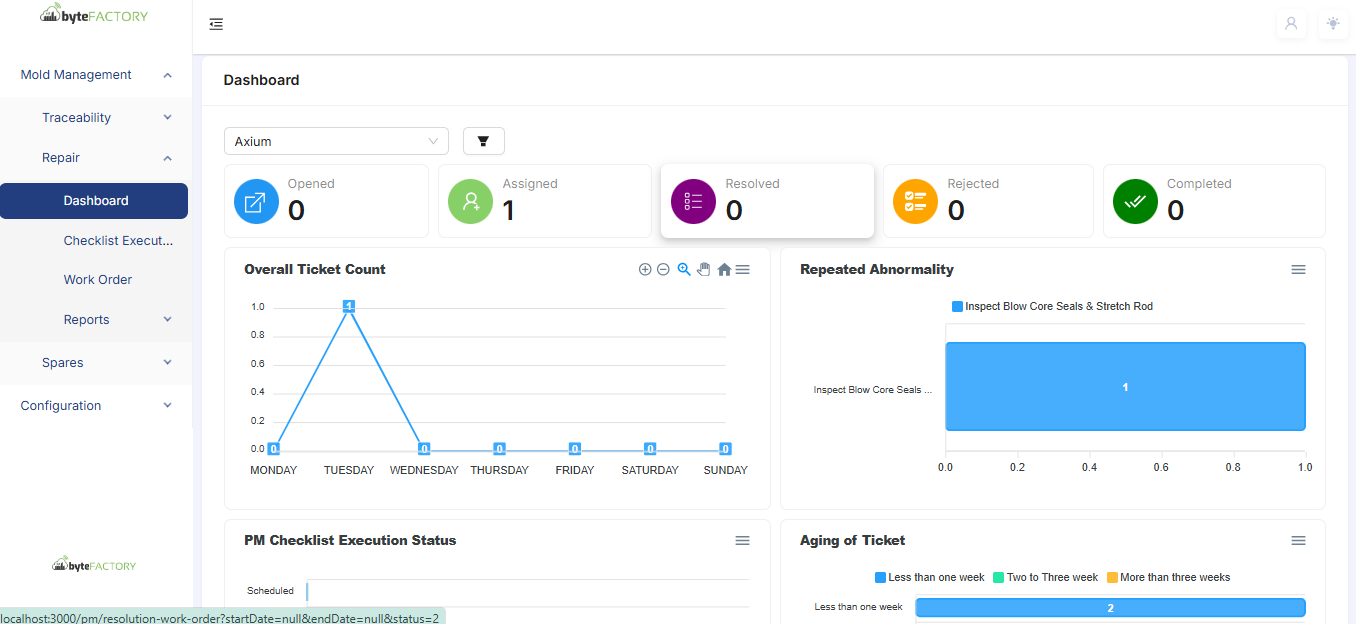

The Maintenance Module is a centralized system designed to streamline all maintenance activities, ensuring equipment uptime, operational efficiency and safety. It supports various maintenance strategies — Preventive and Corrective — with advanced scheduling, tracking and reporting features. The module enables maintenance teams to manage assets effectively, reduce unplanned downtimes and extend equipment lifespan.

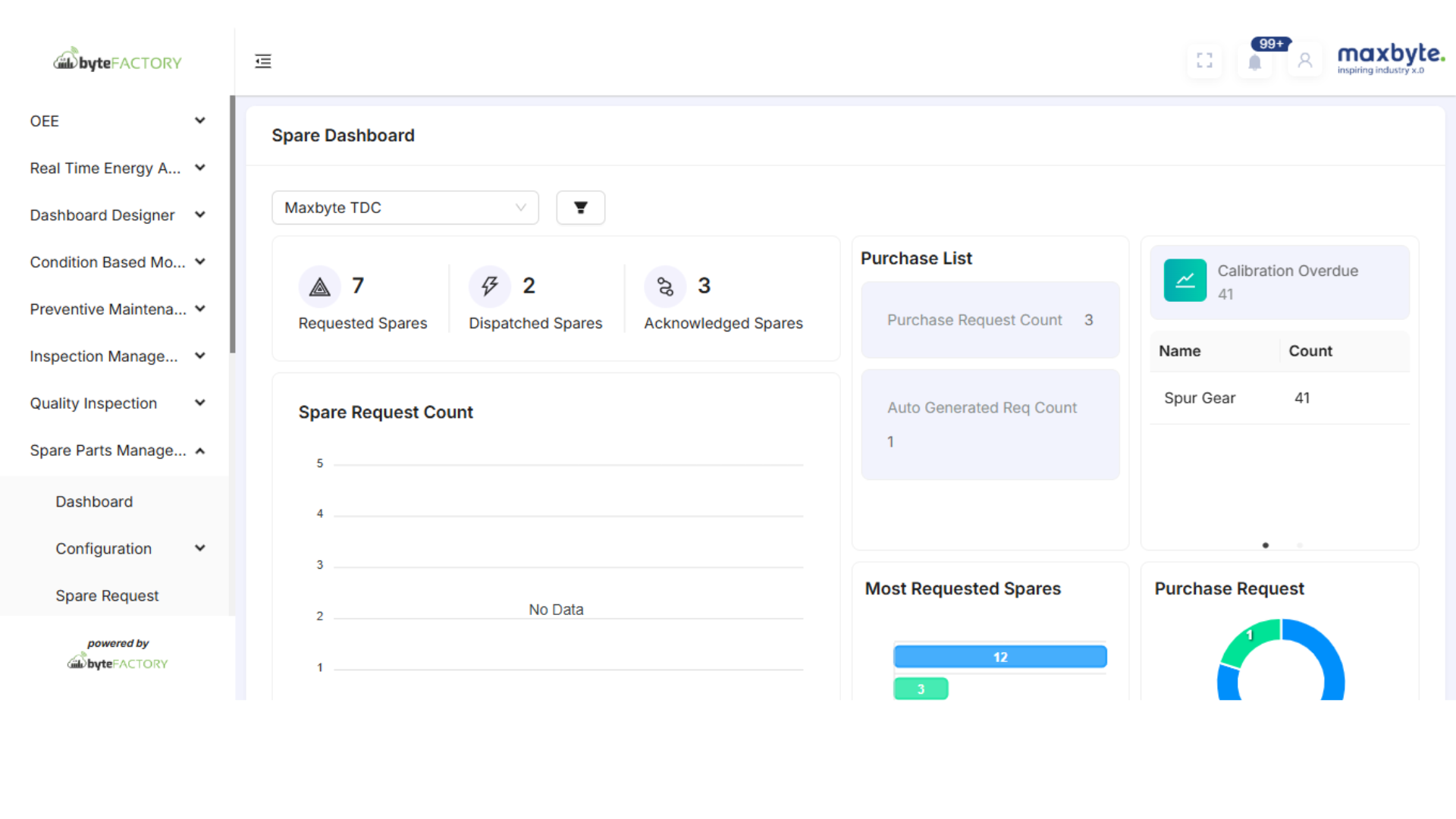

Spare Parts Management ensures that the right parts are available at the right time, reducing machine downtime and optimizing Preventive Maintenance Tasks. By providing real-time visibility into stock level, this module empowers maintenance teams to make informed decisions and avoid delays due to part shortages.