Your Cart Is Empty

✖No products in the cart.

byteFACTORY DAMS bridges IT and OT to turn shop floors into intelligent, connected ecosystems.

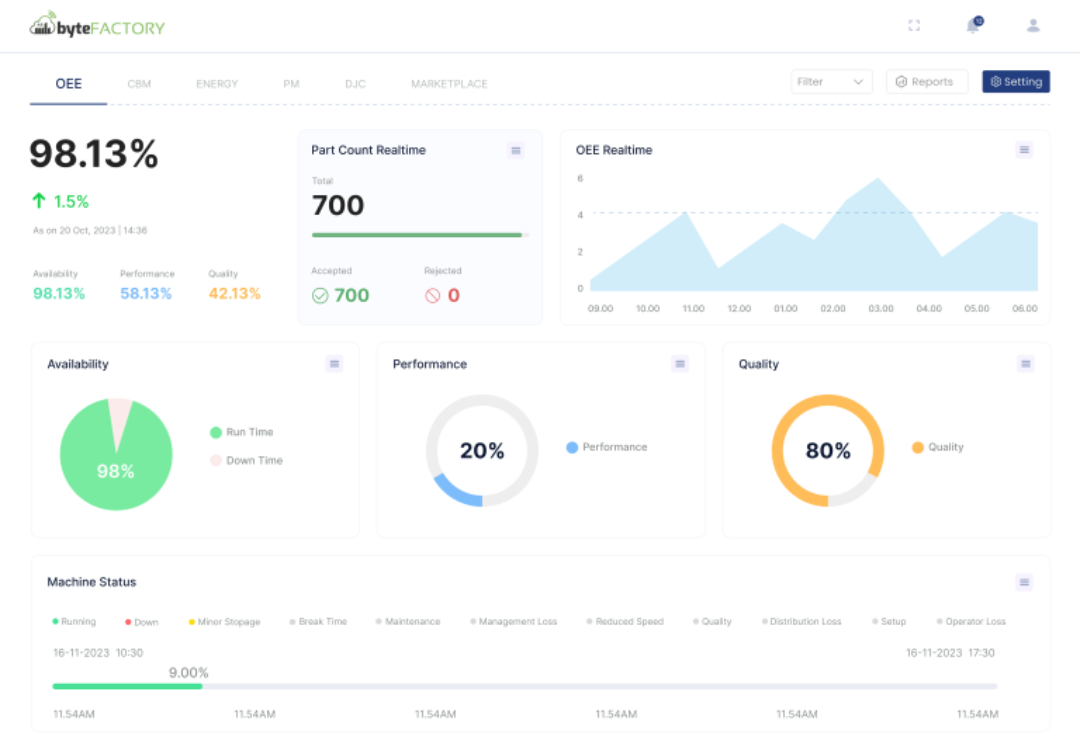

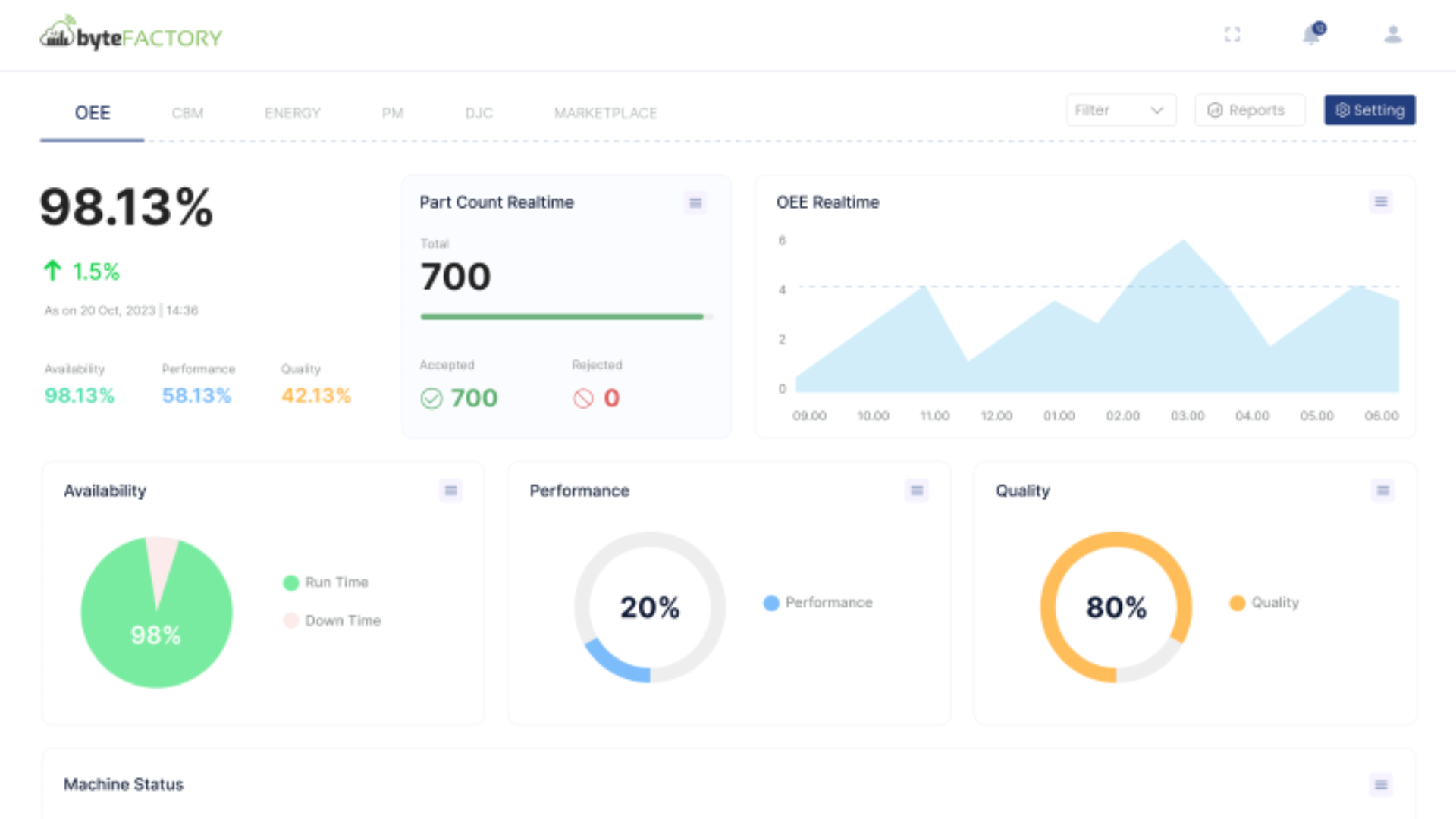

Gain Real-time visibility, Preventive maintenance, and seamless traceability—Driving agility and zero downtime.

Streamline production, reduce waste, and maximize throughput with real-time insights and automated workflows.

Accelerate production cycles and minimize downtime with intelligent scheduling and real-time analytics.

Enhance quality control and reduce material loss through predictive insights and automated issue detection.

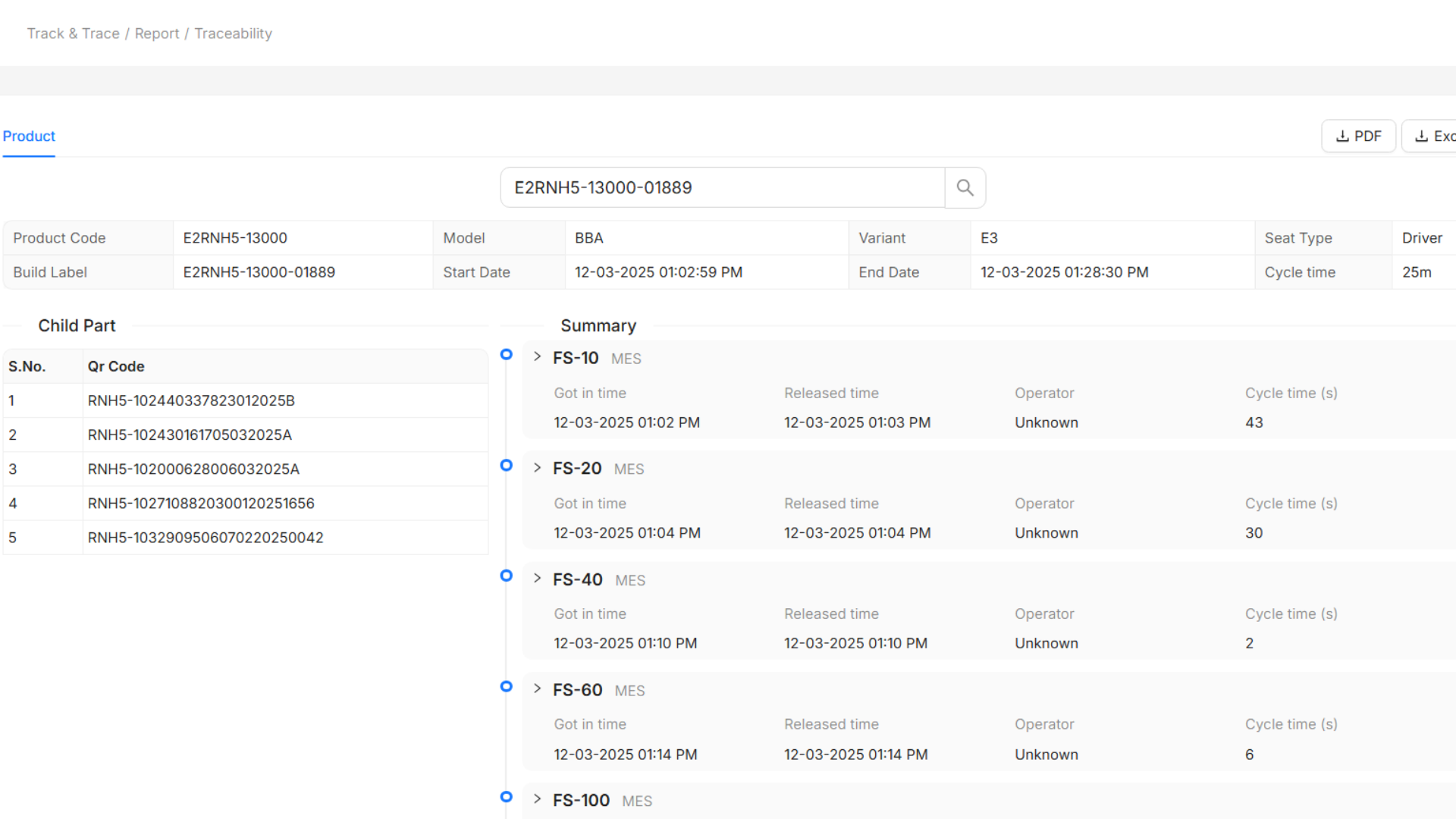

Track every component and process step in real time for full production visibility and faster root-cause analysis.

Adapt quickly to changes in demand, design, or production with flexible, data-driven operations.

Leverage real-time data and actionable insights to drive smarter, faster operational decisions.

Tedious manual entry & paper trails, Hidden inefficiencies slowing you down, Constant firefighting on the shop floor.

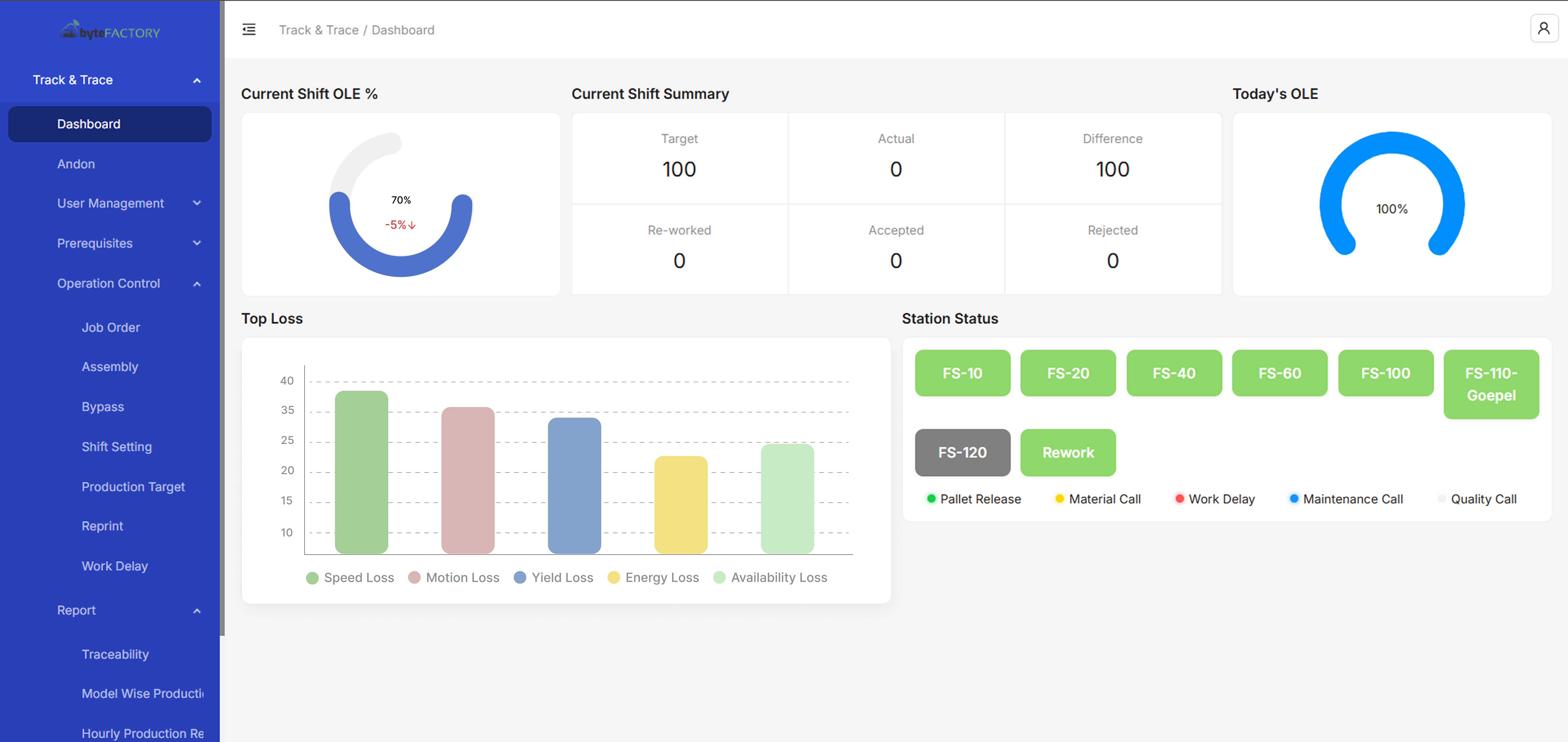

Real-time visibility across every station and shift, Data-driven decisions for operators and supervisors, Seamless IT + OT integration with zero downtime, Proactive alerts that prevent problems before they escalate

Innovative Solutions: Delivering cutting-edge technology tailored for industrial automation and smart manufacturing.

Reliable Performance: Ensuring consistent, high-quality results with every deployment and integration.

Customer-Centric Approach: Focusing on your unique needs to drive efficiency and business growth.

End-to-End Visibility: Monitor each step of production and logistics in real-time for complete control.

Actionable Data: Harness both historical and real-time data for improved product quality and regulatory adherence.

Effortless Connectivity: Integrate smoothly with current systems to ensure seamless traceability throughout the process.

https://bytefactory.ai/wp-content/uploads/2025/12/Lightweight-MVP-𝐛𝐲𝐭𝐞𝐁𝐎𝐀𝐑𝐃.mp4We’ve built a lightweight MVP called 𝐛𝐲𝐭𝐞𝐁𝐎𝐀𝐑𝐃 — a Generative ...

Read MoreFrom Language Models to Autonomous Agents: The Evolution of ...

Read MoreIn manufacturing, scale matters—but the right solution matters even ...

Read More